Small Conveyor Applications

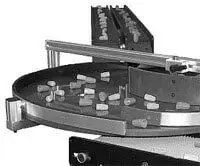

Conveyor Product Transfer

For long or varied production lines, product transfer between stations or conveyor units is important for efficient work flow and ensures sensitive parts smoothly through junctions. Lite Series conveyors, LP Series conveyors and Transfer-Station equipped RTA Rotary Table Accumulators can be used singly or in combination to meet these operational requirements.

Objets d’Art

Exhibit designers and visual arts professionals most often choose Mini-Mover Conveyors in their projects. The affordable Lite and LP Series conveyors are easy for non-engineers to modify, integrate and maintain -- perfect for artists on a budget. Because we at Mini-Mover Conveyors quite enjoy collaborating in a creative process that the public can enjoy, we're quite happy to participate in bringing fascinating artistic projects to fruition.

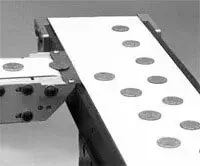

Metalworking

Mini-Mover Conveyors were originally introduced to meet the needs of metalworking businesses, such as metal stamping, punch press, CNC lathe, screw machine and lights-out robotic operations, to name a few.

Incline/Decline Conveyor Operations

Incline and decline conveyors are useful in moving product from one elevation to another, and can also be used to help match up height on the production line. The modularity of our small conveyors allow for the incline or decline angle of your needs.

Inspection

Product inspection can involve many types of functions and systems as part of the user’s quality-control or packaging operations. Mini-Mover small conveyor modules are easily integrated into visual inspection, metal detection, x-ray inspection and checkweighing systems.

Diverting and Surge

In temporary buffering or surge control scenarios, product can continue to feed into a diversionary conveyor or area of a conveyor. This is useful when the main line stops intermittently, when product needs to divert to a workstation for separate actions, or when product delay is needed to prepare downstream operations to receive product.

Lab, Medical and Cosmetics

The needs of cosmetic products during the production process can combine many application types for which our small, clean Mini-Mover Conveyors are highly suited. Our Lite Series and LP Series miniature conveyors are proven choices for small, delicate product handling -- including but not limited to capping, barcode scanning, inkjet printing, labeling and checkweighing and x-ray inspection.

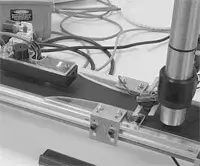

Code Printing

Coding systems using either ink jet or laser print are a vital packaging component across many industries, with specialization made in various system types for the shape, size and material of container as well as the setup of the production line. Mini-Mover small and miniature conveyors have proven to be popular components in side-, top- and bottom-transport style package and vision coding systems. Both Lite and LP Series conveyors are cost-effective, scalable and highly adaptable -- making them an ideal choice for integration into a variety of systems.

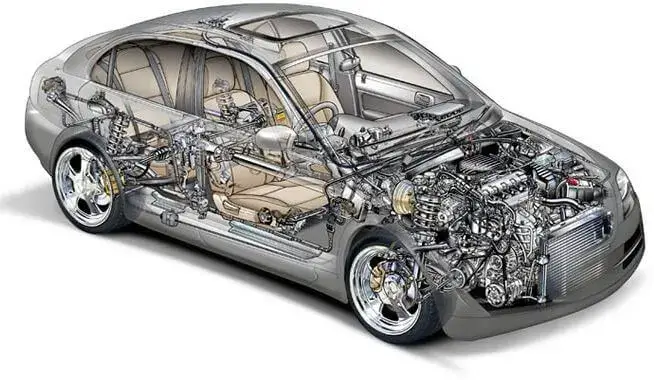

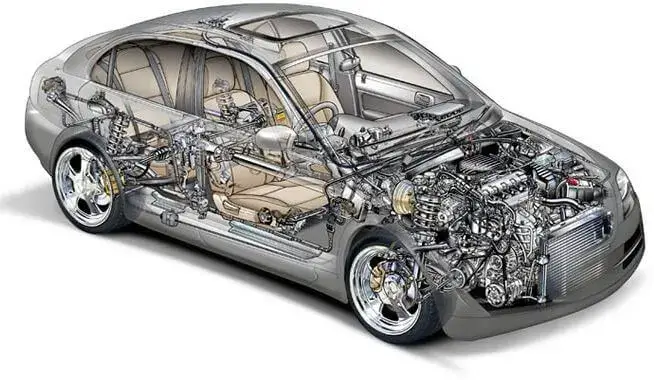

Automation

The smooth operation and compact size or our Mini-Mover conveyor modules make them ideal for handling sensitive, small precision parts. As the needs of your automotive production evolves, or as production lines are repurposed the modularity and portability of our Lite Series and LP Series small conveyors and rotary accumulation tables makes for an easy transition whether it is a change that occurs from month to month or shift to shift.