Getting started in automation, or adding to an already existing line, doesn’t have to be rocket science. A sensible way to start is to identify your prime work-flow bottleneck(s) or repetitive tasks that don’t need skilled decision-making.

Greater efficiency even with staff shortages is entirely possible, if you automate repetitive tasks. Free up your skilled personnel for the cognitive work they need to do, and automate those repetitive jobs that a machine can do faster.

Whether it’s in your R&D lab, machine shop, inspection station or assembly operation, our professionals at Mini-Mover Conveyors can work with you to find solutions that you can actually afford and are easy for every worker to use.

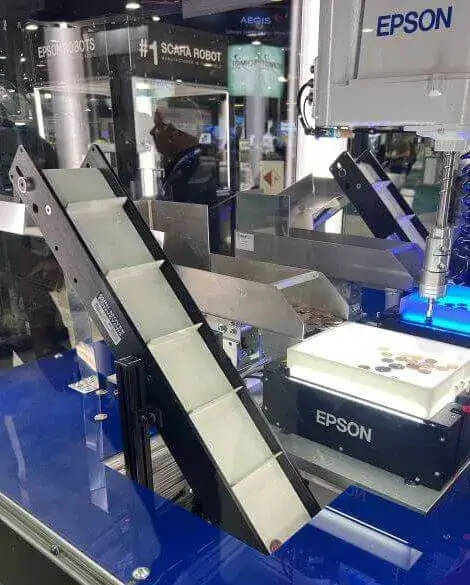

System integrators – who deal with automation integration – value our robotics friendly and PLC compatible conveyors. Mini-Mover Conveyor products are often an integral part of larger, complex automation systems aimed at high-scale output.

For our manufacturing customers who make volume parts, they’ll add in of our Rotary Table Accumulators (RTA) or Uni-Mate® to their machines, to gather finished parts — freeing the operator to do other things.

We offer two lines of versatile small conveyors, with each unit built personalized to suit your operating needs. They’re portable and can easily be re-purposed to perform various jobs within a single day. Your overall workflow can run more smoothly and profitably.

Give us a call, and we can help build a solution for you.