2. Select Belts and Cleats

The following table shows the most commonly used and cost-effective belting we offer. These selections are comparably priced and suitable for most applications. However, we offer many specialty materials, for uses such as very high temperatures, wipedown, severe chemical exposure and ESD-rated belting for electronics and other static-sensitive environments. Consult with your representative for any questions regarding the most suitable belt material for your application.

Flat Belting Materials by Model No. Designation

| Attributes | U1 | U1-CR * | U3 | U4 |

|---|---|---|---|---|

| Top Cover | Urethane | Urethane | Fabric | Urethane |

| Lateral Stability | 2 ply polyester | 2 ply polyester | 2 ply polyester | 2 ply polyester |

| Bottom Side | Fabric | Fabric | Fabric | Fabric |

| Edges | Cut | Heat Sealed | Cut | Cut |

| Color | White | White | White | White |

| Thickness | 0.06″ | 0.06″ | 0.06″ | 0.06″ |

| FDA Conformance | Yes | Yes | Yes | Yes |

| Temperature Range | -22° to 176°F † | -22° to 176°F † | 14° to 158°F | -22° to 176°F † |

| Antistatically Equipped | Yes | Yes | Yes | Yes |

| Cut/Abrasion Resistance | Excellent | Excellent | Fair | Good |

| Top Surface | Medium Gloss | Fabric | Satin | Low Gloss |

| Top Adhesion/Friction | Med-Adh (Med-Frct) | Med-Adh (Med-Frct) | Non-Adh (Med-Frct) | Non-Adh (Low-Frct) |

*U1C belts have heat sealed edges

†U1, U1C, U4 and U5 belts will withstand product temperatures of up to 212°F in applications where product contact is transitory. Temperature values given above are based on continuous or prolonged product contact that elevates or decreases belt material temperature. Contact your representative for assistance with high-heat applications.

| Attributes | P1 | P2 | P3 | P4 |

|---|---|---|---|---|

| Top Cover | PVC | PVC | PVC | PVC |

| Lateral Stability | 2 ply polyester | 2 ply polyester | 2 ply polyester | 2 ply polyester |

| Bottom Side | Fabric | Fabric | Fabric | Fabric |

| Edges | Cut | Cut | Cut | Cut |

| Color | Black | Grey | Dk Grey | Green |

| Thickness | 0.08″ | 0.07″ | 0.16″ | 0.08″ |

| FDA Conformance | No | No | No | No |

| Temperature Range | 32° to 158°F | 23° to 122°F | 14° to 140°F | 14° to 158°F |

| Antistatically Equipped | Yes | Yes | Yes | No |

| Cut/Abrasion Resistance | Good | Good | Excellent | Good |

| Top Surface | Matte | Waffled | Waved Grid | Smooth |

| Top Adhesion/Friction | Non-Adh (Low-Frct) | High-Adh (High-Frct) | V-High-Adh (High-Frct) | High-Adh (Med-Frct) |

Cleated Belts

Cleats (also called carriers) can be added to flat belting in order to separate or support products, especially in incline & decline applications. Cleats are available on all U-style belts except the U3. Standard cleat styles and sizes are shown below, which are those most commonly used. Cleat heights other than those listed here are also available upon customer request. Please contact your sales representative for non-standard cleat configurations.

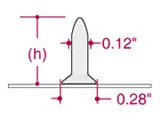

H-Cleat - 90° Upright

| Style | (h) in. | (h) mm |

|---|---|---|

| H0 | 0.16″ | 4mm |

| H1 | 0.79″ | 20mm |

| H2 | 1.18″ | 30mm |

| H3 | 1.58″ | 40mm |

| H4 | 2.36″ | 60mm |

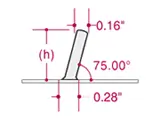

K-Cleat - 75° Angle

| Style | (h) in. | (h) mm |

|---|---|---|

| K5 | 0.50″ | 12mm |

| K6 | 1.00″ | 25mm |

| K7 | 1.50″ | 38mm |

| K8 | 2.00″ | 51mm |

| K9 | 2.50″ | 64mm |

Application Suggestions

All Purpose

- Assembly Line

- Inspection

- Metal Stamping

- Automotive Mfg.

- Plastic Molding

Clean Applications

- Food Packaging

- Medical Mfg.

- Laboratory

- Electrical Mfg.

- Cosmetics

Material Handling

Incline & Decline

- High Grip

- Impact Loads

- Medium Grip

Special Usage

- Bar Code

- Ink Jet/Code Printing

- Low-Noise

- Severe Duty