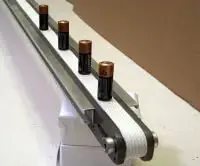

Mini conveyor belt systems can solve many problems associated with limited space or moving small, delicate parts. Sometimes the miniature conveyor is needed to be built right into the machine or work cell. Then there are cases where small delicate parts need to be moved through safely in an already cramped production facility. Dedicating the extra space for a more common, bulky conveyors is unnecessary when mini conveyor belt systems are available. With the reduction of space that mini conveyor systems allow, increased production space is opened for other activities. Mini Conveyor products offered are the Low Profile (LP) Series small conveyor and the ready-to-run Lite Series miniature conveyor.

The breadth of options and accessories allows for a custom small conveyor setup that fits your needs. The various options are ready-to-run (plug and play) conveyors with integral drive packages; modular drive packages, motor voltage options, belt options, drive mount positions, and conveyor options. The “accessory categories are guides & rails, part stops, couplers & drive shaft (LP Series), product indexing timer, product guide cushions, mounting brackets and conveyor stands.

-

-

- What Exactly is a Mini Conveyor? While are many types of conveyors, there are many “names” used by various manufacturers to describe their smaller sized units. Whatever name is used — micro conveyors, mini belt conveyors, miniature conveyors, small conveyor systems — they’re units intended for use in confined spaces and/or for small or sensitive products.

- What is the Typical Size Range for a Mini or Miniature Conveyor? Here at Mini-Mover Conveyors, we build each mini conveyor to order. We consider narrow width, short length and low profile. Our smallest miniature conveyor size is 1 inch wide by 6 inches long, with a 1.5-inch profile (height). More typically, customers use mini conveyor systems from the 12-inch length and longer. Width varies, but our widest offering is 16 inches wide. Our largest standard size is 16 inches by 144 inches long — but we can go longer with our extended-length option. No two mini conveyors we build are exactly alike.

- Are Mini Conveyors Very Versatile? Absolutely! Our miniature conveyors can be configured in countless ways to serve a wide array of purposes and industries. They are often integrated into CNC machines to unload parts or scrap material. They are designed into capping systems, labeling systems, hopper systems, vibratory feeder systems, stamping presses, clean room labs, vision systems, pharmacy counters — you name it. Often, Mini-Mover mini conveyor systems are accessorized for tabletop use or with stands for added portability on our larger miniatures.

- Can Mini Conveyors Withstand Rigorous or Constant Use? The terms “mini conveyor” or “miniature conveyor” can be misleading. In all sizes, Mini-Mover Conveyors are industrial strength and can run loads up to 150 lbs., depending on size and gearmotor selection. Ours are built in solid aluminum and assembled in an “I” beam construction, making them extremely strong and rigid. Daily usage or 24/7 operation over a span of years is common for Mini-Mover users. The Mini-Mover construction method also allows great flexibility in width selection.

Since our miniature conveyors and small belt conveyors are highly portable, please refer also to our pages on Tabletop Conveyors and Portable Conveyors for more configuration ideas.

-