Rise of the (Affordable Automation) Machine!

Last year really showed us that manufacturing automation is on the rise for companies small and large. It’s not always beyond-budget. Yet, there’s a real concern among many in the industry that this move toward greater efficiency and productivity will eliminate human jobs. We believe jobs will expand as a result of automation initiatives.

Conveyors, for example, help to automate ordinary, tedious manual tasks and allow the worker to focus on or be trained to take on more multifaceted and intellectual jobs. This skills migration also allows for a confidence build-up in automation technology for those companies reluctant to do take on such processes. Conveyors don’t take jobs away, they make the work people do become more valuable, rewarding and safe.

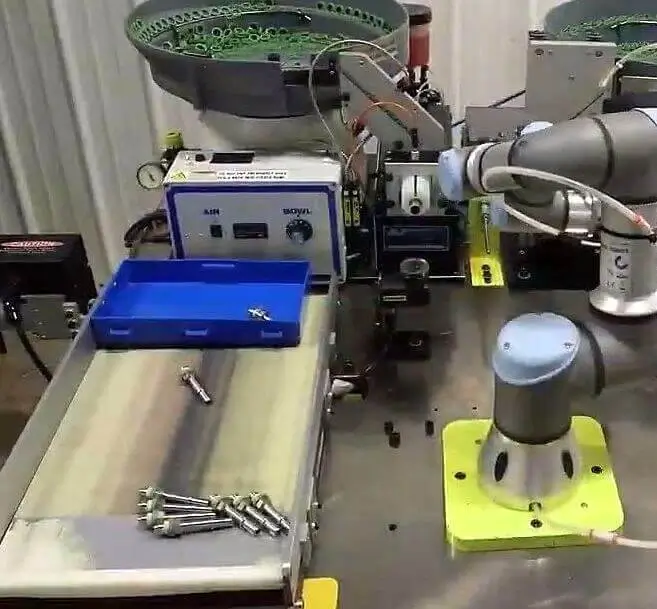

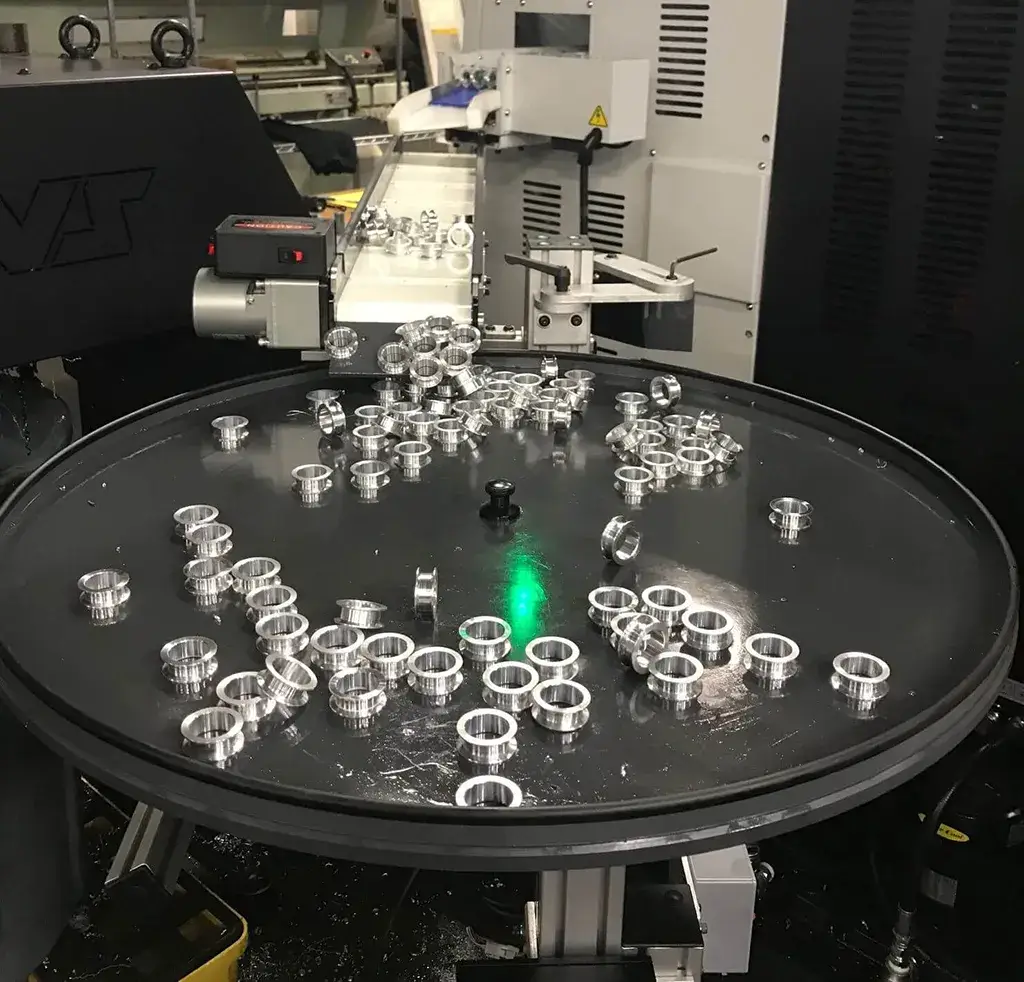

As Jeff Melville, our National Sales Director puts it, “Having conveyors used in conjunction with our customers machines and robotics allows their team to focus on truly important jobs within their company. No longer are they having people stand around, waiting for parts to drop into box, take them out and set them on a table. The ability to have the conveyors and robots take parts away from the machine to a rotary table or another machine allows operators to work in different areas of the shop creating a more efficient and happier employee. It allows for more precise production, even after hours.”

Cobot with LP Series Mini-Mover Conveyor

Although these seemingly overlooked pieces of equipment have often been regarded as “dumb,” the role they play in today’s “intelligent” automation in today’s settings – such assembly, metalworking, packaging, coding and laboratory — has never been more important. Conveyors provide essential links between pieces of automation to transport material with minimal human effort. The very fact that they can be designed to fit a cell, whether it be a few inches long and wide, up to several integrated systems that can stretch miles, makes them invaluable to any process.

Product needing to be in a certain place at a certain time can no longer be subject to production and delivery guessing games. Because conveyors can be controlled in so many different ways, they are the mainstays that solve so many of these manufacturing concerns. PLC’s and accessories like encoders, can monitor and control the belt’s speed and revolutions for precise movements. Cameras, printing heads, counters, proximity switches are now standard items in a conveying system. Stands and mounting options, belting materials, and accessories are so configurable, it makes almost every conveyor these days a “personalized” one. Guessing games have now become predictable, controllable, and efficient standard operating procedures.

Precision Machining with Lite Series Conveyor and Mini-Mover RTA Accumulator

A full automation strategy isn’t necessarily required for everyone. Simple approaches to relieving areas that don’t really need human skill or intervention are a great place to start. If there is an area where boxes or parts are being moved by hand, ask us about how a conveyor can be built to fit your needs.