Ease Transition into Automating Ink Jet Printing/Coding

As a small business increases its sales volume, the need to upgrade manual methods for inkjet product labeling or case-coding may seem like a daunting expense. It doesn’t have to be. There are entry-level and mid-level products that can make the switchover affordable. Mini-Mover Conveyors are often used by packaging vendors to complete a case-coding or ink-jet printing system package. Shown here are a few examples from Pro-Pack Solutions, Inc. of Loganville, Ga.

Pro-Pack specializes in entry-level to mid-level packaging equipment,allowing a business to progressive grow its capability. Here are the various Pro-Pack ink-jet and case coding solutions that use Mini-Mover Conveyors to transport products along the line.

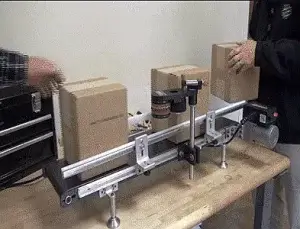

Case Coding with Mini-Mover LP Series Conveyor

Side Mounted Pro-Pack Ink Jet Printer with Mini-Mover LP Series Conveyor

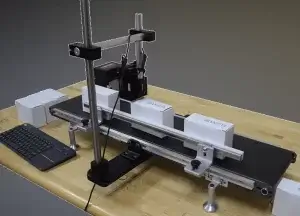

Complete Pro-Pack ‘Smart-Jet Blue’ Package with Mini-Mover LP Series Conveyor