Avoid Downtime: Simple Preventative Maintenance

In the big world of conveyors, Mini-Mover Conveyors are remarkably simple and inexpensive to maintain. But by giving in to the temptation to “save” money by skimping on your routine maintenance checks or essential spares inventory, it can cost you a lot more in the long run.

Three (3) Essentials to Keep on Hand

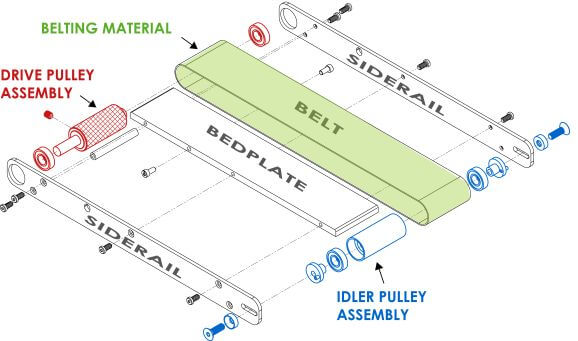

We purposely simplify our product designs to keep the number of replacement maintenance parts to a minimum. There are only three (3) essential items to keep on hand for quick, fast maintenance. Depending on your conveyor usage and configuration, you might wish include gearmotor components.

- Spare belt. Most replacement belts we have in stock. But if we made it especially for your conveyor, such as a custom belt material or with cleats, it’s best to stock a spare.

- Spare Drive Pulley Assembly. This is the knurled pulley that’s driving your gearmotor. When you’re changing out a belt, it’s good to check out this pulley too. Drive pulleys can collect debris more readily than the smooth Idler pulley. It may be just fine with a bit of cleaning. But a spare will help ensure you can keep running if replacement is needed. (And we provide a pulley complete assembly, since when one component such as a bearing seems worn, it maybe have affected others parts in the assembly. Why chance it?)

- Spare Idler Pulley Assembly. This has a smooth surface. The Idler Pulley should be checked at the same time as the Drive end. It may not need replacement as the same time since the two ends provide differing functions.

Eliminate Costs of Lost Time and Throughput

For lack of a simple spare part, the operation of your work cell or even a whole line can be disrupted. Consider your potential losses:

- Time Lost – Workers must redirect or stop work while the part is ordered and shipped. If production can actually continue manually while the conveyor is down, it will take more time, possibly with more people, to complete the job.

- Output Lost – Downed machines endanger production deadlines, which can cost the company more money, time and valuable client relationships.

- Bottleneck Created – If the conveyor is part of a bigger work cell or floor process, affected machines (and the work) downstream might need to be entirely shut down while waiting for new parts.

- Expedite Fees for Shipping or Production – If you need a part shipped by next-day air, the shipping charge could actually be more than that of the part itself. If your part is custom, such as a cleated or special-material belt, there’s more delay to get a quick shipment to you.

It’s vital to keep even a small stock of your most commonly maintained spares. It’ll keep your conveyors running smoothly and keep disruption to a minimum. We even have some customers who stock complete, spare conveyors, which they “hot swap” on essential production lines, allowing maintenance on the alternate conveyor to be done offline.

For more information on Mini-Mover maintenance and spares ordering, contact our Customer Service Dept at 800-586-4585, or email [email protected].