Mobile Lite Conveyor & Vision System for Auto Parts Inspection

SPEDE Technologies, a manufacturing automation company based in Cleveland, OH, designed and fabricated a “mobile conveyor parts counting/verification system” around a Lite Series Mini-Mover conveyor.

One of SPEDE’s specialties is developing systems for Honda suppliers, to enable them to meet Honda MPRs (Minimum Process Requirements) for identifying, counting, tracking, packing, labeling and traceability of Honda parts.

With this SPEDE system, the human out of the counting/verification is automated at packaging time by using combinations of technologies — such as vision sensors, PLC controls, diverters, weigh scales, etc.

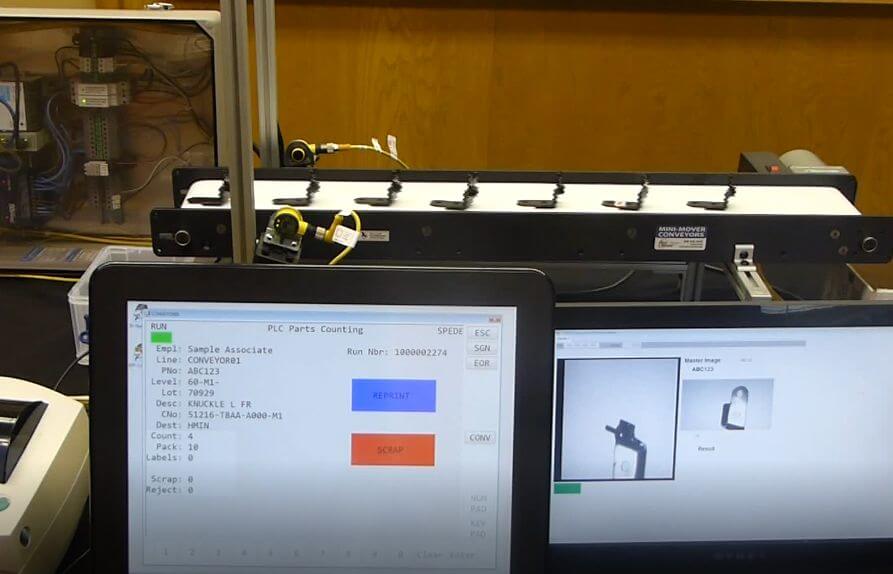

Portable SPEDE Inspection System with Mini-Mover Conveyor

This portable SPEDE system is designed to precisely count parts using a Keyence Vision Sensor as the parts are conveyed underneath the sensor. The counted parts can be dropped or diverted into a container or hand-packed into special dunnage, as necessary, for Honda. The conveyor can be of various widths and lengths to accommodate different part sizes. It can be mounted on a mobile cart to be moved from line to line as needed to ensure packaging accuracy on each line.

Here are the components of SPEDE’s mobile conveyor solution:

- a mini conveyor of appropriate size,

- a T-slot framework holding the conveyor along with a Keyence Vision Sensor

that is mounted overhead, - a presence sensor to detect a part on the moving belt and to trigger the

Keyence Vision Sensor to take an image of the part and to analyze the image for

the correct part (and with no defects), - a PLC control panel to control the conveyor and diverter and to take action if a

defective part is detected, - a touchscreen PC with our client SPEDE software running on it, connected to a

local network in order to update EDI and ERP and shipping systems, - an optional monitor so the operator can see the real-time image of each part

just as the Keyence sensor “sees” it, - and a Zebra direct thermal printer connected to the touchscreen PC to print

the Honda label automatically when the pack count of good parts is reached.

For more information on how Mini-Mover Conveyors can help in your automation initiatives, call us at 1-800-586-4585.